OVERVIEW : smart emg based robotic arm project

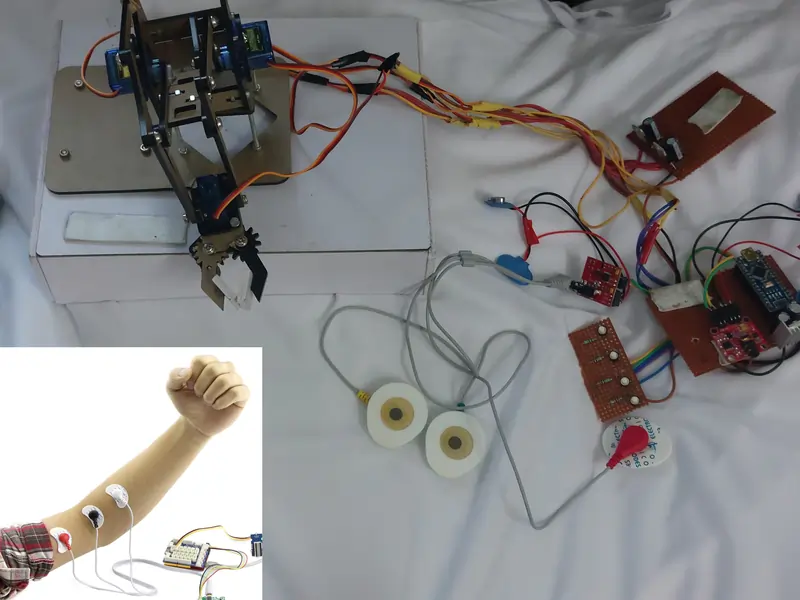

This project report outlines the development and implementation of a robotic arm system based on EMG muscle sensors. The primary objective of the project was to design a mechanism that could accurately detect and replicate arm movements using a combination of EMG muscle sensors, servo motors, and an Arduino Nano microcontroller. By harnessing the signals generated by the user's muscles during arm movement, the robotic arm was able to mimic these actions in real-time.

The project involved a comprehensive review of existing research in the field of EMG-based robotics, which guided the selection and integration of appropriate components. The hardware design incorporated EMG muscle sensors to capture muscle activity, servo motors to control the robotic arm's movement, and an Arduino Nano for signal processing and actuation. The software architecture focused on mapping the EMG signals to corresponding servo motor movements, ensuring precise replication of the user's arm motion.

A series of experiments were conducted to evaluate the system's performance. The results demonstrated the successful detection and replication of arm movements by the robotic arm, showcasing the potential for applications in fields such as rehabilitation and human-robot interaction. The project not only provided valuable insights into the integration of EMG muscle sensors with robotic systems but also served as a stepping stone for future enhancements and advancements in the field.

OBJECTIVE:

The objective of this project is to design, develop, and implement an EMG muscle sensor-based robotic arm system that can accurately detect and replicate human arm movements. By integrating EMG muscle sensors, servo motors, and an Arduino Nano microcontroller, the project aims to create a functional prototype capable of providing precise and responsive control over the robotic arm's movements. The ultimate goal is to demonstrate the feasibility and potential applications of EMG-based robotics in fields such as rehabilitation, prosthetics, and human-robot interaction.

PROBLEM STATEMENT:

The project addresses the challenge of creating a robotic arm system that can closely mimic human arm movements. Existing robotic systems often lack the level of precision, dexterity, and intuitive control required to replicate the complexities of human arm motion. This poses limitations in fields such as rehabilitation, where precise replication of arm movements is crucial for effective therapy and motor skill relearning. The project aims to overcome these limitations by harnessing the power of EMG muscle sensors to accurately detect and interpret muscle signals, enabling the robotic arm to replicate the user's arm movements with high fidelity. By doing so, the project seeks to bridge the gap between human and robotic capabilities, opening up opportunities for more natural and effective human-robot interaction and assisting individuals with motor impairments in their rehabilitation process.

Working of the Project:

The EMG muscle sensor-based robotic arm system operates by capturing and interpreting the electrical signals generated by the user's muscles during arm movements. These signals are processed and mapped to control signals that actuate the servo motors, which in turn drive the robotic arm's joints and end effector. The Arduino Nano microcontroller plays a central role in processing the signals and coordinating the overall control of the system.

Working of EMG Sensor:

The EMG muscle sensor consists of electrodes that are placed on the surface of the user's skin, typically over the muscles of the forearm. When the user initiates an arm movement, the corresponding muscles generate electrical signals. The EMG sensor detects these signals and converts them into analog voltage variations. These voltage variations represent the muscle activity and are proportional to the intensity of muscle contractions. The EMG sensor provides a real-time stream of muscle signals, capturing the user's arm movements.

Working of Servo Motor:

The servo motor is a rotary actuator that allows for precise control of angular position. It consists of a motor, a gear mechanism, and a feedback control system. The servo motor receives control signals in the form of pulse width modulation (PWM) signals. The width of the PWM signal determines the desired angle of rotation. The servo motor's internal control system uses the feedback from an integrated position sensor to accurately move the motor shaft to the specified angle. This closed-loop control mechanism ensures that the motor maintains the desired position.

Working of Arduino:

The Arduino Nano microcontroller acts as the brain of the system, coordinating the EMG sensor data and servo motor control. It receives the analog voltage signals from the EMG sensor and processes them using analog-to-digital conversion. The microcontroller then applies signal processing algorithms to filter and interpret the muscle signals. Based on the processed signals, the Arduino generates PWM control signals for the servo motors. These control signals are sent to the servo motors through appropriate GPIO pins. The Arduino continuously monitors the muscle signals, updates the control signals, and ensures the robotic arm replicates the user's arm movements in real-time.

APPLICATIONS

The EMG muscle sensor-based robotic arm project has various potential applications in different fields. Some of the key applications include:

Rehabilitation: The project can be utilized in rehabilitation settings to assist individuals with motor impairments or injuries. By accurately detecting and replicating arm movements, the robotic arm can facilitate targeted muscle exercises, promote motor recovery, and provide a platform for therapy and motor skill relearning.

Prosthetics: The technology developed in this project can be extended to the field of prosthetics. By using EMG muscle sensors to control prosthetic limbs, individuals with limb loss can regain more natural and intuitive control over their prostheses. This can greatly enhance their quality of life and improve their ability to perform daily activities.

Assistive Devices: EMG-based robotic arms can serve as assistive devices for individuals with physical disabilities or limited mobility. By translating muscle signals into robotic arm movements, these devices can help individuals perform tasks that would otherwise be challenging or impossible. This includes activities such as grasping objects, reaching for items, or manipulating tools.

Industrial Automation: The project's technology can find applications in industrial automation and human-robot collaboration scenarios. EMG-controlled robotic arms can be used to enhance productivity and safety in manufacturing environments. Workers can guide the robotic arms using their own arm movements, allowing for more efficient and intuitive interaction between humans and robots.

Research and Development: The project can be utilized as a research and development tool in the field of robotics. Researchers can explore and test new algorithms, control strategies, and sensor integration techniques using the EMG-based robotic arm platform. This can contribute to advancements in the field and lead to the development of more sophisticated robotic systems.

These applications highlight the versatility and potential impact of the EMG muscle sensor-based robotic arm project. By enabling intuitive and responsive control of robotic arms, the technology can be applied in various domains to improve rehabilitation processes, assist individuals with disabilities, enhance industrial automation, and drive advancements in robotics research and development.

ADVANTAGES

Intuitive and Natural Interaction: The use of EMG muscle sensors enables intuitive and natural interaction between the user and the robotic arm. By detecting the user's muscle signals, the system can replicate their arm movements, providing a more intuitive and responsive control interface compared to traditional methods.

Enhanced Precision and Control: The integration of EMG muscle sensors, servo motors, and Arduino microcontrollers allows for precise control over the robotic arm. The EMG signals provide real-time feedback on the user's muscle activity, enabling accurate replication of arm movements by the robotic arm. This enhances precision and control, making the system suitable for applications that require precise manipulation and positioning.

Adaptive and Personalized: The project offers adaptability and personalization based on the user's unique muscle activity patterns. By analyzing and learning from the user's EMG signals, the system can adapt to individual variations and provide personalized control of the robotic arm. This ensures a comfortable and tailored user experience, accommodating different users with varying levels of muscle activity and abilities.

Improved Rehabilitation and Therapy: In rehabilitation settings, the project can aid in the recovery and therapy process for individuals with motor impairments. The ability to replicate natural arm movements can facilitate targeted muscle exercises, enabling more effective rehabilitation and motor skill relearning. The system can provide real-time feedback and monitoring, assisting therapists in assessing and tracking the progress of patients.

Versatility and Applications: The project's technology can be applied in various fields and applications. It can be used in rehabilitation centers, prosthetics, assistive devices, industrial automation, and research and development. This versatility allows for the system to address different needs and cater to a wide range of users, expanding its potential impact and utility.

Cost-Effective Solution: The project offers a cost-effective solution compared to more complex and expensive robotic systems. By leveraging readily available components such as EMG muscle sensors, servo motors, and Arduino microcontrollers, the system can be developed and implemented at a relatively lower cost without compromising functionality and performance.