1. Introduction:

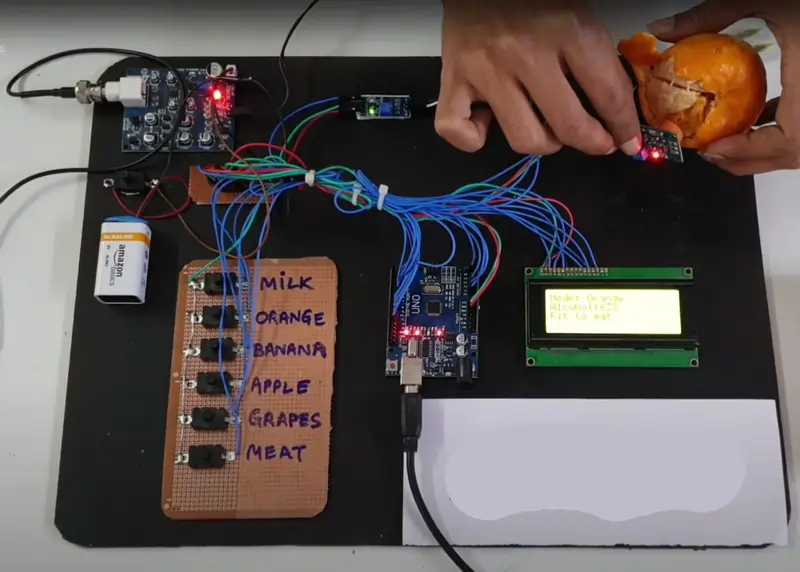

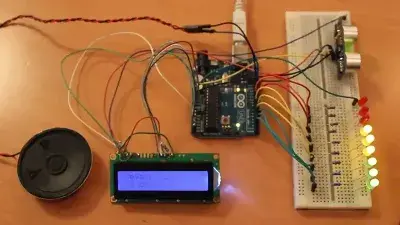

The Arduino-based food freshness detection project aims to address the critical issue of food spoilage by developing a system that can effectively monitor the freshness of various food items. The project utilizes Arduino microcontrollers along with pH, moisture, and methane sensors to assess the quality and freshness of food items such as milk, oranges, bananas, apples, grapes, and meat. The detection system offers a cost-effective and efficient solution for consumers and food industries to ensure the safety and quality of food products.

2. Literature Review:

Previous studies have highlighted the importance of monitoring food freshness to prevent foodborne illnesses and reduce food waste. Arduino-based projects have been increasingly employed in sensor-based applications due to their versatility and accessibility. Research on pH sensors, moisture sensors, and methane sensors has shown their efficacy in detecting various parameters related to food quality and freshness.

3. Materials and Methods:

The project utilizes the following components:

1.Arduino microcontroller board

2.pH sensor

3.Moisture sensor

4.MQ4 methane sensor

5.Various food items (milk, oranges, bananas, apples, grapes, meat)

6.The sensors are calibrated to detect specific parameters indicative of food freshness. The Arduino board collects data from the sensors and processes it using programmed algorithms to determine the freshness of the food items. The circuit is designed and assembled to interface the sensors with the Arduino board effectively.

4. Experimental Setup:

The experimental setup involves:

Calibration of each sensor using standard solutions or reference materials

Connection of sensors to the Arduino board as per the circuit diagram

Placement of food items in designated containers or compartments for monitoring

Execution of the Arduino code to collect sensor readings and analyze freshness parameters

5. Results and Analysis:

Experimental data is collected for each food item, including pH levels, moisture content, and methane presence. The results are analyzed to determine the correlation between sensor readings and food freshness. Comparative analysis is conducted to assess the effectiveness of the detection system across different food items.

Working of the Arduino-Based Food Freshness Detection System:

1. Sensor Calibration:

Before monitoring food items, each sensor undergoes a calibration process to ensure accurate readings. Calibration involves exposing the sensors to known reference materials or standard solutions that represent the desired freshness parameters. For example:

> pH sensor calibration involves immersion in solutions of known pH levels.

> Moisture sensor calibration requires exposure to dry and wet reference materials to establish baseline readings.

> MQ4 methane sensor calibration involves exposing it to methane gas of known concentrations.

2. Data Collection:

Once calibrated, the sensors are connected to the Arduino microcontroller board as per the circuit diagram. The Arduino board is programmed to collect data from the sensors at regular intervals. Each sensor provides real-time readings of specific freshness parameters:

pH sensor measures the acidity or alkalinity of the food item.

Moisture sensor detects the moisture content present in the food.

MQ4 methane sensor detects the presence of methane gas, which can indicate spoilage in certain food items.

3. Data Processing and Analysis:

The Arduino board processes the sensor readings using programmed algorithms to analyze the freshness parameters of the food items. The algorithms compare the obtained sensor values with predetermined thresholds or reference values to determine the freshness status. For example:

pH levels outside the optimal range may indicate spoilage or fermentation.

High moisture content could suggest the onset of mold or bacterial growth.

Presence of methane gas may indicate microbial activity in perishable food items such as meat.

4. Real-Time Monitoring:

The system continuously monitors the freshness of the food items throughout their storage or transit period. Users can periodically check the freshness status and take appropriate actions such as consuming, refrigerating, or discarding the food items based on the displayed information.