Abstract:

The project aims to develop a smart ignition system for vehicles using load cell and Arduino to detect and prevent overloading. Overloading is a significant concern that can lead to accidents, increased fuel consumption, and accelerated wear and tear on vehicle components. The proposed system will continuously monitor the vehicle's weight and provide real-time feedback to the driver. The integration of Arduino, load cell, and a user-friendly interface will ensure enhanced safety and optimized vehicle performance. This report provides a detailed account of the design, development, testing, and implementation of the Arduino-based smart ignition system.

1. Introduction:

Overloading of vehicles poses significant risks to road safety and vehicle performance. This project aims to design and implement a smart ignition system that detects overloading in real-time using load cells and an Arduino-based microcontroller. The system will provide immediate feedback to the driver, allowing them to take corrective action and avoid potential hazards. This report outlines the objectives, scope, and key features of the proposed project.

2. Literature Review:

The literature review explores existing research on vehicle overloading, load cells, and the versatility of Arduino in various applications. Understanding the background and past efforts in this area will help in the effective design and implementation of the proposed smart ignition system.

3. System Design:

This section presents the system's architecture, including a block diagram depicting the flow of data and control. It also describes the various components used in the project, such as the load cell, Arduino board, and user interface. The process of load cell calibration to ensure accurate weight measurement is also discussed.

4. Arduino Programming:

The programming section focuses on the Arduino code developed to interface with the load cell and process the acquired data. The logic to determine the weight threshold for overloading and control the vehicle's ignition based on this threshold is elaborated upon.

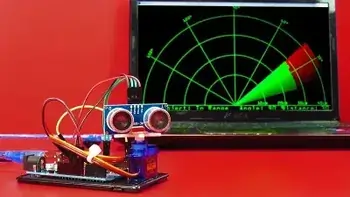

5. User Interface Development:

A user-friendly interface is crucial for the effective operation of the smart ignition system. This section explains the design and development of the user interface, including display options, driver interaction, and warnings or notifications to ensure prompt responses to overloading situations.

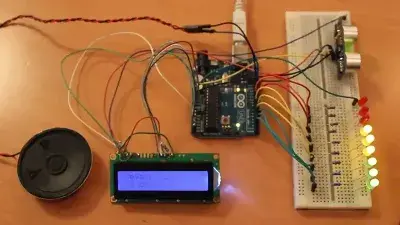

6. Hardware Implementation:

Here, the physical implementation of the system is detailed. The integration of the load cell with the vehicle's chassis, the connection of Arduino to the load cell and other components, and the power supply circuit are discussed.

7. Applications:

1. Automobile Industry: Prevent overloading, enhance vehicle safety, and optimize performance.

2. Transportation: Ensure compliance with weight regulations for trucks and trailers.

3. Logistics: Real-time monitoring of cargo weight to prevent overloading and potential damage.

4. Fleet Management: Improve efficiency by preventing excessive wear and fuel consumption.

5. Construction: Monitor material loads on trucks, promoting safer transportation.

6. Agriculture: Enhance tractor and equipment safety by preventing overloading.

7. Waste Management: Optimize waste collection vehicles and reduce maintenance costs.

8. Emergency Vehicles: Monitor weight for safe operations during critical missions.

9. Off-road Vehicles: Prevent overloading for safety and vehicle longevity.

10. Specialized Vehicles: Cater to specific industries with tailored weight monitoring solutions.

7. Advantages:

1. Improved Vehicle Performance: Optimal weight distribution reduces fuel consumption and wear on components.

2. Regulatory Compliance: Ensures adherence to weight limits and avoids costly fines or penalties.

3. Cost Efficiency: Minimizes maintenance expenses by preventing damage caused by overloading.

4. User-Friendly Interface: Intuitive display and notifications enable easy driver interaction and response.

5. Versatility: Applicable across various industries, from transportation to agriculture and construction.

6. Real-Time Monitoring: Continuous weight data ensures timely action to avoid critical situations.

7. Sustainable Practices: Reduces carbon footprint through optimized vehicle operations.

8. Customizability: Can be adapted to suit specific vehicle types and load requirements.

9. Technological Innovation: Showcases the potential of Arduino-based projects for practical solutions.

7. Testing and Validation:

The system's functionality and performance are validated through comprehensive testing procedures. The calibration testing of the load cell, Arduino, and the user interface is carried out, and the results are analyzed.

8. Results and Discussion:

This section presents the results obtained from the testing phase and discusses the system's overall performance. The benefits and limitations of the smart ignition system are critically evaluated.

9. Conclusion:

The conclusion summarizes the achievements of the project, emphasizing its significance in addressing vehicle overloading issues. It also suggests potential improvements and future enhancements to further refine the system's capabilities.

In conclusion, the load cell and Arduino-based smart ignition system offer an innovative approach to tackle the problem of vehicle overloading, promoting road safety and optimizing vehicle efficiency. By providing real-time feedback to drivers, this system empowers them to take proactive measures and prevent hazardous situations. The project's detailed design, implementation, and testing, as outlined in this report, establish a solid foundation for the continued development and application of similar Arduino projects to address various real-world challenges.