Abstract

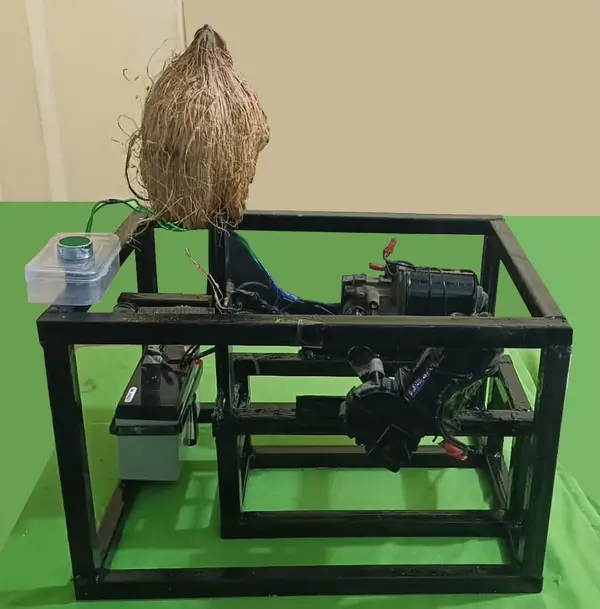

Coconut processing industries face challenges in efficiently removing coconut husks, a labor-intensive task that impacts productivity and operational costs. To address this issue, we have developed a semi-automatic coconut remover machine. This innovative machine utilizes a combination of sharp spikes, spring mechanisms, electric motors, and a sturdy metal structure to streamline the husk removal process while minimizing manual labor requirements.

The design of the semi-automatic coconut remover machine prioritizes efficiency, safety, and versatility. Sharp spikes, arranged in a cylindrical configuration, penetrate the coconut husk under controlled force provided by a spring mechanism, facilitated by electric motors. This ensures consistent and uniform husk removal, resulting in high-quality coconuts for further processing. Additionally, safety features are integrated to prevent operator injury, making it a reliable and safe solution for coconut husking tasks.

Overall, the semi-automatic coconut remover machine represents a significant advancement in coconut processing technology. Its potential to increase productivity, reduce labor costs, and improve operational efficiency makes it a valuable asset for coconut processing industries. With further optimization and refinement, this machine has the capability to revolutionize husk removal processes, contributing to the growth and sustainability of the coconut industry.

APPLICATIONS

1. Coconut Processing Industries: The primary application of the semi-automatic coconut remover machine is in coconut processing industries where coconuts are husked for various products such as coconut water, coconut milk, coconut oil, and coconut-based snacks. The machine streamlines the husk removal process, improving efficiency and productivity in coconut processing operations.

2. Food and Beverage Manufacturing: The machine finds application in food and beverage manufacturing facilities where coconuts are used as ingredients in various products. By automating the husk removal process, the machine enhances production efficiency and ensures consistent quality in coconut-derived food and beverage products.

3. Agricultural Cooperatives: Agricultural cooperatives involved in coconut farming and processing can benefit from the use of the semi-automatic coconut remover machine. The machine reduces reliance on manual labor, thereby lowering labor costs and increasing the profitability of coconut processing activities within the cooperative.

4. Export Industry: Coconut husks are often removed before exporting coconuts to international markets. The semi-automatic coconut remover machine helps meet the quality standards and efficiency requirements of export-oriented coconut suppliers. It ensures uniform husk removal and enhances the market competitiveness of exported coconuts.

5. Research and Development: The project has applications in research and development initiatives focused on improving coconut processing technologies. Researchers and engineers can study the performance and optimization of the semi-automatic coconut remover machine to develop advanced husk removal solutions for the coconut industry.

6. Small-Scale Coconut Processing Units: Small-scale coconut processing units, such as local coconut oil extraction facilities or coconut-based product manufacturers, can benefit from the use of the semi-automatic coconut remover machine. It offers an affordable and efficient solution for husk removal, enabling small-scale producers to enhance their production capabilities.

ADVANTAGES

1. Increased Efficiency: The semi-automatic coconut remover machine enhances efficiency by automating the husk removal process, reducing manual labor requirements, and increasing throughput in coconut processing operations.

2. Improved Productivity: By streamlining husk removal processes and increasing operational throughput, the machine significantly improves productivity, allowing for higher production output and reduced processing time.

3. Enhanced Safety: Incorporation of safety features and protocols ensures a safer working environment for operators, minimizing the risk of accidents and injuries during machine operation.

C4. onsistent Quality: The machine's ability to achieve uniform husk removal results in higher-quality coconuts suitable for further processing into various products, ensuring consistent product quality standards and customer satisfaction.

5. Cost Savings: Reductions in labor costs, increased productivity, and improved operational efficiency lead to significant cost savings for coconut processing industries, contributing to overall profitability and competitiveness.

CONCLUSION

In conclusion, the development and implementation of the semi-automatic coconut remover machine have demonstrated significant advancements in coconut processing technology. The machine represents an innovative solution to the challenges associated with manual husk removal methods, offering improved efficiency, productivity, and operational safety in coconut processing operations.

The results obtained from the project highlight the machine's ability to streamline husk removal processes, increase throughput, and enhance product quality standards. By automating the husk removal process, the machine reduces reliance on manual labor, resulting in cost savings and higher operational efficiency for coconut processing industries.

Furthermore, the incorporation of safety features and protocols ensures a safer working environment for operators, contributing to improved workplace safety standards. The machine's consistent and uniform husk removal capabilities enhance quality control standards, leading to higher-quality coconut products with increased market competitiveness.