A dual side shaping system is a mechanical device that uses two shaping wheels or rollers to shape a material, such as metal, plastic, or wood, from both sides simultaneously. This type of system can be used for a variety of applications, such as fabricating metal parts, shaping plastic or wood components, or creating custom designs on various materials.

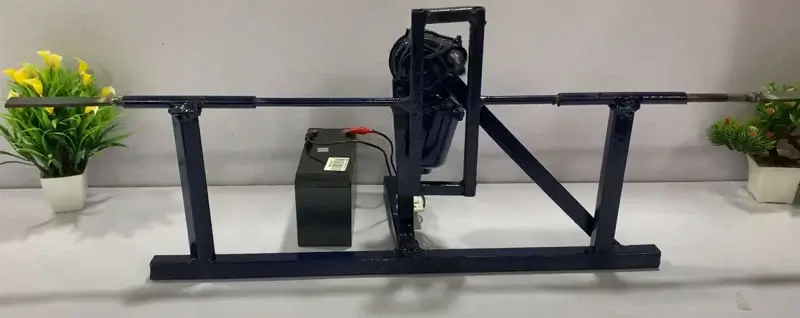

To build a dual side shaping system, you will need two shaping wheels or rollers, a motor, a power supply, and a frame to hold the components in place. You will also need to design and build a mechanism to control the movement of the shaping wheels, ensuring that they are aligned and synchronized during operation.

Once built, the system can be used to shape materials quickly and accurately from both sides, creating uniform and precise results. This type of system can be particularly useful for shaping curved or irregular shapes, as it provides even pressure from both sides of the material.

One of the advantages of a dual side shaping system is its versatility and efficiency. With the ability to shape materials from both sides simultaneously, this type of system can save time and improve productivity in a variety of settings. It's also relatively easy to maintain and adjust, making it a reliable and cost-effective solution for many applications.

Building a dual side shaping system is a challenging but rewarding project that can help you develop new skills in mechanics and engineering. Whether you're a hobbyist or a professional fabricator, this type of system can be a valuable addition to your workshop or production line. So why not take on the challenge and build your own today?